We are proud to have alumni representing the University of Washington’s Materials Science & Engineering department in our local community and across the world.

There are so many ways to stay connected, no matter what year you graduated! Attend an alumni event such as the MSE Research & Industry Showcase, follow us on social media, volunteer to be a mentor or sign up to receive the Roberts Hall Review alumni newsletter.

Resources

UW Engineering Diamond Award winners

2023 Translating innovation into impact

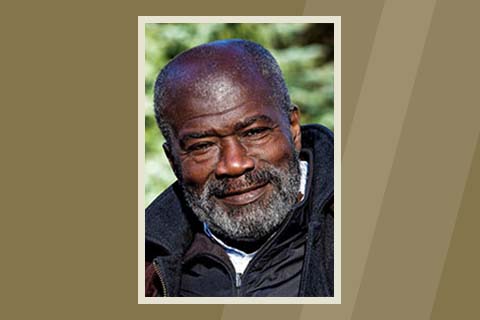

Alain Adjorlolo, B.S. 1979 MSE; M.S. 1981 MSE; Ph.D. 1985 MSE

Alain Adjorlolo's technical advances have influenced modern aircraft design and advanced sustainability across the industry.

Alain's bio

2018 Entrepreneurial Excellence

Aaron Feaver, Ph.D. 2007 MSE

Aaron Feaver is a pioneer the development of new low-carbon dioxide energy sources. His commitment to developing solutions in clean energy has solidified Washington state as a leader in the movement.

Aaron's bio